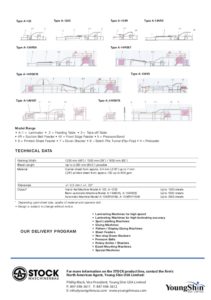

STOCK A Model

|

Sheet length:

|

Min. 18”, max. 80.05”

|

|

Sheet width:

|

Min. 15.75″, max. 49″ or 1250 mm

Min. 15.75”, max. 59” or 1500 mm

Min. 15.75”, max. 65” or 1650 mm

Substrate sheets should be approximately 0.19” – 0.31” smaller in length and width compared to the printed sheets always. High noise levels result when running with transversal flute direction (lying flutes); therefore, corrugated sheets should run with standing flutes. Running lying flutes enforces the use of earmuffs (ear protection) for the operators.

|

|

Substrate /Carrier Sheets:

|

– Single-face corrugated board of B-/C-/E-/F- and G-flute. – Single and double wall corrugated up to 0.27” caliper (5 layers): EE-/EB-flute etc. – Double-double open face combinations up to 0.27” (4 layers): EE-/EB-flute etc. – Solid board from approximately 0.02” thickness / caliper (~ 350 – 400 gsm) upwards, dependent upon material quality. The pre-loading height in the magazine of the feeder is restricted/limited. The board used should have a smooth surface when mounting thin paper. Otherwise wrinkles and blisters will affect the product quality. Thin board only by use of a bar with stripping needles. – Applied sheets are dependent upon material (sheet) quality, size, flatness and weight. Different materials can cause deviations in production and quality. |

| Top Sheets: | Offset pre-printed paper and cardboard sheets (labels) approximately 150 – 600 gsm. Printed sheets should be run with grain traverse (short grain) to the flute direction of the corrugated sheets. Suitable label sizes dependent upon basis weight, grain (direction) and material quality. Running odd shaped labels could result in minor performances and other difficulties. Perimeter (edge) waviness leads to wrinkles and bubbles. |

| Accuracy: | Approximately ± 0.02” in the accurate mode. Variation in register depends on sheet (material) quality, especially flat sheets, grain direction, paper and board dimension and calliper (weight), sheet size and squareness, machine condition, minimum glue application, etc. |

| Adhesive: | We recommend white resin PVAc glue, viscosity about 3,000 – 4,000 mPas. Glue consumption – dependent upon the material quality, kind of flutes, content of moisture, conditions of the glue rollers, etc. for: – single-face corrugated board sheets: about 22 – 30 gsm, from B- up to F-flute. – full surface application: about (35) 40 – 60 gsm – dependent on sheet quality. |

| Laminating Process: | The laminating section aligns the sheet against the side guide and mechanical head stop for precise registration. |

| Pressure Belt: | The pressure belt flattens the sheet and allows the adhesive to properly cure and assists in the removal of bubbles and creases. |

| Down Stacker: | An automatic non-stop down stacker and optional inverter are available. |

| Output: |

Performance dependent on sheet size, especially sheet length, material quality, sheet flatness and weight (calliper), grain direction, operators’ skill and machine conditions. Output values are indicated for using flat quality sheets. Restrictions are placed on output for odd shaped blanks and labels. Maximum performance possible: Automatic Machine Model A-14R5PS6M: for sheet length Increased sheet length affects the production and causes less production. Top performances can be achieved with qualified operators and quality material only. Deviations result from interruptions, disturbances, feeder charging, pallet changes etc. Staff requirement: 1 – 2 operators for an automatic machine with automatic sheet take-off, dependent on sheet length (size) and machine performance. Deviations result from machine interruptions, disturbances, feeder charging, pallet change etc. |

| Carrier Sheet Feeder 4R: | – suction-belt (hopper) feeder, manual pre-feeding with sheet batches – pre-piling height corrugated board: up to 14” | dependent on sheet – pre-piling height – suitable for continuously (non-stop) sheet feeding – sheet / pile warpness: up to maximum 0.8” per 40” sheet width – suitable with restrictions for carton and solid board |

| Production: | Manual – 1,200 sph Semi-automatic – 2,000 sph Fully automatic – 3,500 sph |

| Printed Sheet Feeder 6M: | – back-edge feeder, added on the top of the machine, with suction head – without non-stop – standard pre-piling height – labels: up to 12” – pile weight: maximum 500 kg – printed sheet loading: from the side of the feeder, by use of a separate pre-loading table beside the machine, as well as air-tables – maximum pile / sheet warpness: up to 0.787” per 39.37” sheet width |

| Auto. Delivery Model 5PS: | – combined pressure up-stacker unit, for automatic sheet delivery – pile height: maximum up to 63” – including the pallet, not using roller conveyors – without a mechanically non-stop device – includes an option for pallet change in a non-stop mode – with reduced speed and a short machine stop (automatic stop and restart of the machine) – time limitation for pallet change – pallet exit is recommended cross to the machine direction – safety protection by a safety barrier system |

| Set-Up Time: | Approximately 10 – 20 minutes with two (2) operators, in accordance with practical experience to the changes to be affected and skill of the operators. |

| Power Supply: | Model A-14R5PS6M: 30 kW; fuses 3 x 63 amps; terminal connection: 3 phases + neutral + earth. |

| Line Voltage: | – 230/400 volts, 60 cycles; transformer will be supplied by Young Shin USA – mains voltage fluctuations: maximum +/- 10% – mains power frequency fluctuations: +/- 2.5% – control voltage: 24 VDC |

| Switchboard: | Temperature sphere (operation temperature) in the control cabinet: 5 – 40° C. Otherwise it is necessary to use an air conditioning unit for the control cabinet. |

| Motors: | A.C.-motors with frequency controllers: Siemens, Lenze, KEB, SEW, Nord servo motors and controllers: Siemens |

| E-Control: | microprocessor Siemens, PC477, with 12” touch-screen and S7 |

| Air Supply: | 6 bar compressed-air; connection ¼”. Air requirement: approximately 200–300 l/min. (free air) for a 1” diaphragm glue pump, feeding PVAc adhesive, viscosity approximately 3,000 – 4,000 mPas (cp), as well as some pre-blowing air for sheet separation in feeder 6M. |

| Color: | RAL 7035, grey |

| Foundations: | Special foundation plates are not necessary, just pits in the ground floor |

| Operator’s Side: | B-side – left-side (in running direction of the machine) |

| Floor Space: | Space requirement Model A-134R56M, approximately 49’-2” x 14’-9” x 13’-1” (length x width x height) |

All technical data represent maximum values, dependent on sheet size, paper weight (caliper), conditions and quality of material, specifically flatness, as well as conditions of the machine. Extreme values may not coincide in a format. Differences may occur depending on sheet sizes, configurations, paper / sheet weight (caliper), conditions, quality of material, etc.