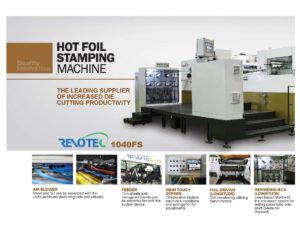

Young Shin Revotec – Foil Stamping and Embossing 1040FS

The Young Shin REVOTEC 1040FS is a hot foil stamping machine. The innovative technology of the 1040FS sets this unit apart from its competitors. The REVOTEC 1040FS only requires a foil path of 6’ as compared to 40’ on other brands. The foil also travels with the sheet in the same direction eliminating the excessive leader often required by other competitors while shortening the foil’s transport and path through the stamper. The REVOTEC 1040FS features the many advantages offered in the highly-acclaimed REVOTEC series including:

- An economical investment with initial and operational cost savings

- UL-certified electronics including UL-wiring

- Offers a 20% greater weight advantage when compared to other rival models

- A 25% greater impressional tonnage capacity

.

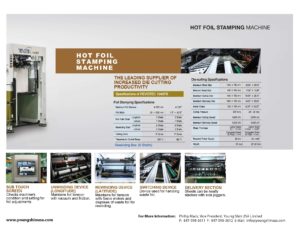

REVOTEC 1040FS Series

| Maximum Sheet Size | 40.94” x 29.13” |

| Minimum Sheet Size | 17.32” x 13.38” |

| Maximum Cutting Size | 40.94” x 28.74” |

| Inside Chase | 43.33” x 30.07” |

| Cutting Pressure | 331 US Tons |

| Maximum Cutting Speed | 6600 sph |

| Maximum Stamping Speed | 5000 sph |

| Sheet Thickness | Carton Board: 0.004” ~ 0.060”

Corrugated Board: (B Flute) : 0.157”) |

| Weight | 22 US Tons |

Foil Stamping

| Maximum Foil Dimension | Ø 7.87” |

| Foil Width | 1.18” ~ 40.15” |

| Foil Puller Sheet – Longitude

Foil Puller Sheet – Latitude |

3 Shafts

2 Shafts |

| Rewinding Shaft – Longitude

Rewinding Shaft – Latitude |

6 Shafts

2 Shafts |

| Heating Zone | 12 Zones |

| Temperature Control Range | 392° F |

| Rewinding Box | 6 Shafts |