STOCK LLM/HP

The STOCK LLM/HP has been designed for fully automatic label laminating including spot or full sheet labeling for the corrugated and display industries. The LLM offers quick set-up and simple operations and can produce up to 5,000 sheets per hour. The equipment utilizes servo driven and laser controlled registration technology that allows adjustments on-the-fly to ensure precise registration. The finished product is stacked label side up for essential quality control. No stereo or mat is needed for adhesive placement.

| Blank width: | Minimum 12” Maximum 64.9” |

| Blank length: | Minimum 14” Maximum 100” |

| Label width: | Minimum 8” Maximum 62.9” |

| Maximum Output: | Up to 31.5” – 5,000 sheets per hour

31.5” up to 49” – 3,000 sheets per hour 49” up to 65” – 2,000 sheets per hour 65” up to 100” – 1,300 sheets per hour |

| Tolerances: | Using automatic registration correction of +/- 1/32” |

| Substrates: | RSC’s, corrugated blanks, chipboard, foamboard up to 0.8” |

| Labels: | Paper and board from 60# up to 10pt |

The STOCK LLM/HP offers a board feeder with a lead edge suction feed with independently driven suction belts that ensure constant and accurate blank feeding.

The equipment also incorporates a lead edge label feeder that utilizes independent suction sleeves that operate on a suction head, providing fast set-up time and consistent label feeding.

The LLM’s vacuumed label application cylinder transfers the glued label to the corrugated blank and offers label control with laser detectors.

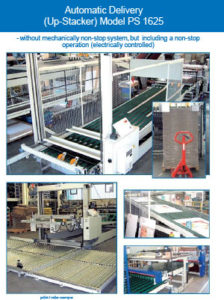

The STOCK LLM’s optional PS 1625 Up-Stacker incorporates a conveying system and optional pallet load that accommodates a fully non-stop environment.