Young Shin GIANT – Models 130(S) and 150(S)

The Young Shin GIANT premier flatbed diecutter series incorporates both high-quality production and the integration of a fully-configured system for maximum productivity. The GIANT’s precise center line technology provides easy and rapid set up of the die board using the unit’s center block. Thin sheets feed smoothly and effortlessly with the GIANT’s enhanced feeding and conveying systems. The innovative air floating device allows easy withdrawal of the cutting plate for optimum operator efficiency. Two cameras are incorporated into the unit. One is placed within the stripping area and one is positioned in the delivery area. A monitor is located in the feed area for operator viewing. A variety of sizes are available to suit the needs of a wide variety of production environments. Young Shin’s EZ Feeder is available as an optional component of the GIANT series further enhancing productivity and profitability.

.

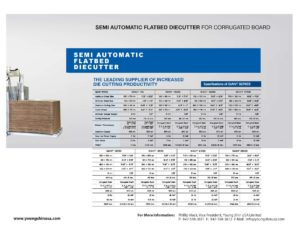

Giant Series

| Model | GIANT 130(S) | GIANT 150(S) |

| Maximum Sheet Size | 51.18” x 37.40” | 59.05” x 43.30” |

| Minimum Sheet Size | 23.62” x 19.68” | 29.52” x 23.62” |

| Maximum Cutting Size | 51.18” x 37” | 59.05” x 42.91” |

| Minimum Gripper Margin | 0.39” | 0.39” |

| Cutting Pressure | 385 US tons | 440 US tons |

| Sheet Thickness | Corrugated Paper (E, B, A, AB Flute) : 0.5” ~ 0.43” |

Corrugated Paper (E, B, A, AB Flute ): 0.05” ~ 0.43” |

| Maximum Speed | 4200 sph | 3600 sph |

| Required Power | 23 AMP | 23 AMP |

| Total Weight | 16.5 US tons | 19.8 US tons |

* EZ Feeder Available for GIANT 130, 150, 170, 180, 190 and 250

|

DIE CUTTING SECTIONChase turnover for easy order change. Knuckle system for maximum cutting pressure. Center line system for quick order change. |

|

STRIPPING SECTIONCenter line system maximizes quick set ups. Quick-lock device for male stripping frame. Triple action stripping (male, female and bottom). |

|

CHASE TURNER (OPTIONAL)Dramatically increases overall productivity and throughput. Allows the next job to be set up while the current job is running. |

|

GRIPPER EDGE REMOVAL DEVICE (OPTIONAL)Full stripping achieved with gripper edge removal device. Discharging gripper edge by auto conveyor. |

|

BATCH DELIVERY SYSTEM (OPTIONAL)Automatic counter ensures batch delivery. Non-stop delivery available via roller conveyor system. Side and back guides deliver perfect stacking. |

EZ-Feeder Specifications |

|

|

SUCTION FEEDStrong vacuum suckers and air separators ensure precise feeding. |

|

WARPED SHEET GUIDE AND FRONT LAY DEVICEWarped sheet device presses down sheet edge for even feeding into front lay assembly. |

|

SHEET SEPARATING BLOWERSAdjustable air pressure and position separates sheets. |

|

SHEET JOGGERSAir cylinder jogging units keep sheets arrayed at rear and sides for enhanced feeding. |

|

FEEDER VIEWPowered by chain transferring device and constant timing by clutch. |

|

MAN-MACHINE INTERFACEDisplays status of machine at all times for quick diagnosis. |

|

EZ FEEDER CONTROL PANELControls all electrical components related to the optional EZ Feeder, if installed. |

|

EZ FEEDER MAIN OPERATION BOXControls the function of the EZ Feeder’s vacuum pump and feeder head movements and engages the feed drive. |