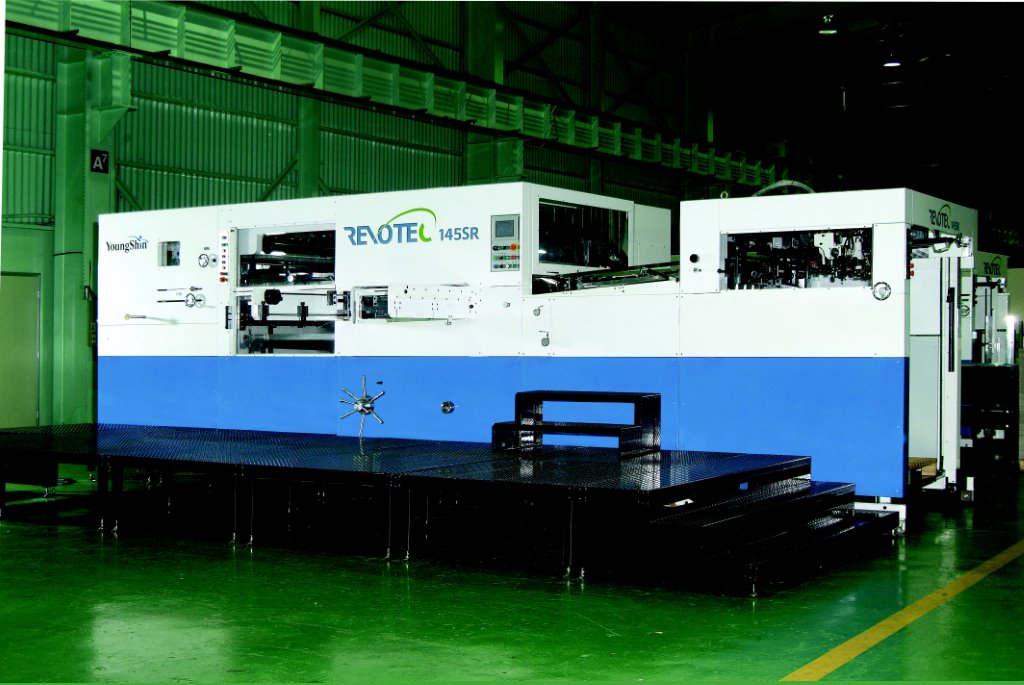

Young Shin REVOTEC Series 145SR

The Young Shin REVOTEC 145SR automatic flatbed diecutter is sized to offer even greater flexibility for a variety of sizes and substrates. Offering increased size capacity, the REVOTEC 145SR incorporates the many advantages offered in the highly-featured REVOTEC series including:

- A highly-economical price point and low operational expenditures

- An integrated lead edge removal system

- Compatibility with Bobst® dies

- Includes an automatic delivery apron that facilitates non-stop delivery

- UL-certified electronics including UL-wiring.

- Offers a 20% greater weight advantage when compared to other rival models

- A 25% greater impressional tonnage capacity

| Maximum Sheet Size | 57” x 40.15” |

| Minimum Sheet Size | 27.55” x 19.68” |

| Maximum Cutting Size | 57” x 39.56” |

| Inside Chase | 60.23” x 46.22” |

| Minimum Gripper Margin | 0.31” |

| Maximum Speed | 6000 sph |

| Maximum Cutting Pressure | 551 US Tons |

| Sheet Thickness | Carton Board: 0.004” ~ 0.060”

Corrugated Board: E,B Flute (Max. 0.157”) |

| Weight | 40 US Tons |

|

FEEDERSheets are smoothly fed driven by the integrated suction device within the mechanical area. |

|

FEEDING CONVEYORMakes the feeding of thin sheets and warped sheets seamless and effective. |

|

SIDE LAYThe side lay provides a sensor to ensure precise registration by approximating the distance between the side and the front . |

|

GRIPPEREnhanced durability for the gripper bar and drive. |

|

CHASEChase turnover and center line ensures quick order change. An air floating device enhances the operational efficiency of the cutting plate. |

|

TOUCH SCREENClear and simple readings ensure quick fault finding and machine operation. Cutting pressure gauge ensures machine and cutting die durability by checking the cutting pressure and over-cutting pressure. |

|

STRIPPING SECTIONWaste stripping is achieved via upper and lower pins. |

|

DELIVERY SECTIONAutomatic counter and tabbing inserter ensures reliability, productivity and batching. |