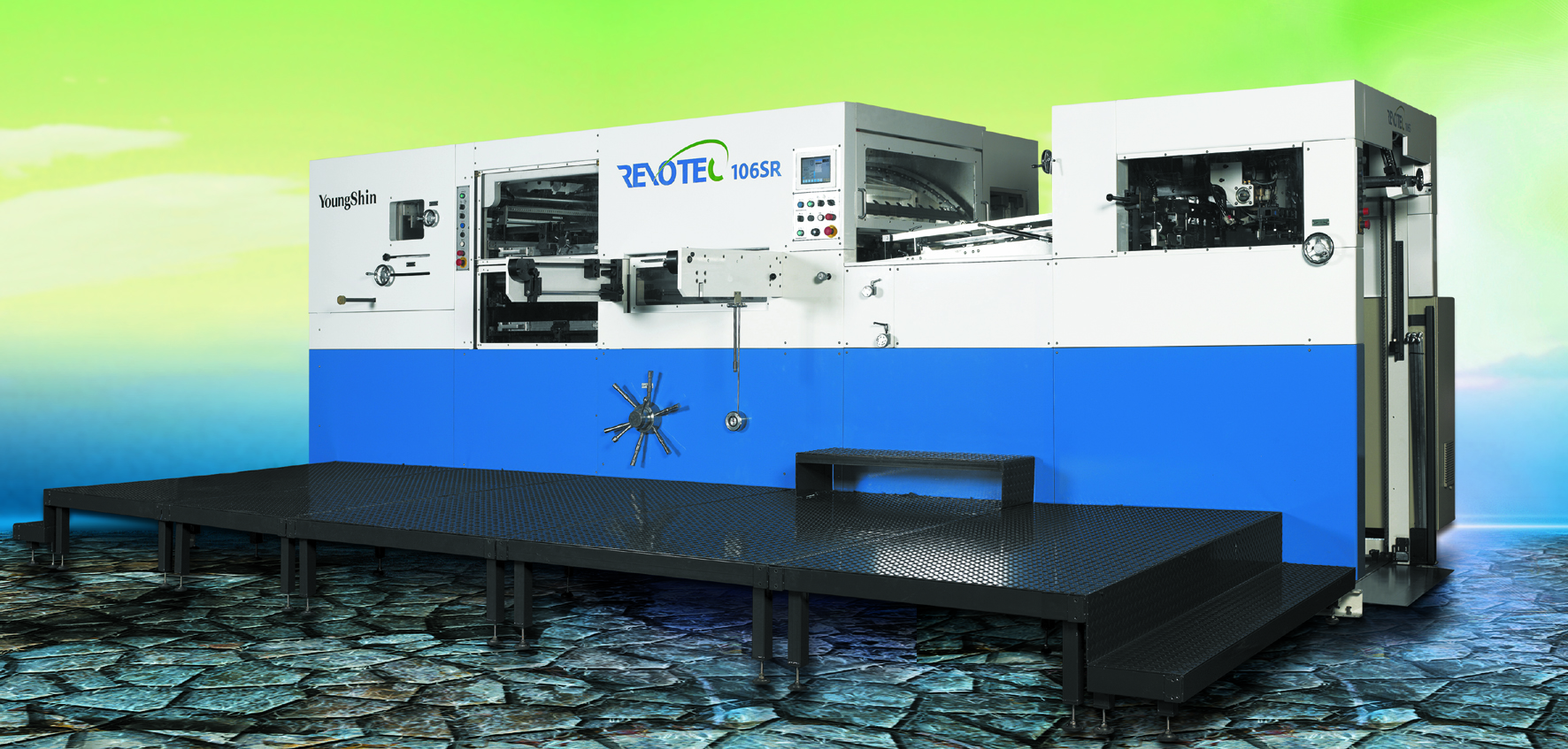

Young Shin Revotec Series 106SR

The Young Shin REVOTEC 106SR (stripping) is an automatic highly-featured flatbed diecutter that offers features and functions far superior to other comparable equipment available in today’s market. The REVOTEC 106SR offers many of the same advantageous features offered in the REVOTEC 106SB including:

- A cost-effective, economical purchase price with low annual operational expenses

- An integrated lead edge removal system

- Compatibility with Bobst® dies

- Includes an automatic delivery apron that facilitates non-stop delivery

- UL-certified electronics including UL-wiring.

- Offers a 20% greater weight advantage when compared to other rival models

- A 25% greater impressional tonnage capacity

| Maximum Sheet Size | 41.73” x 29.92” |

| Minimum Sheet Size | 15.74” x 13.38” |

| Maximum Cutting Size | 41.73” x 29.33” |

| Inside Chase | 44.88” x 29.68” |

| Minimum Gripper Margin | 0.31” |

| Maximum Speed | 7500 sph |

| Maximum Cutting Pressure | 330 US Tons |

| Sheet Thickness | Paper Substrates: 0.004” ~ 0.060”

Corrugated Board: EB Flute (Max. 0.157”) |

| Weight | 21 US Tons |

|

FEEDERSheets are smoothly fed driven by the integrated suction device within the mechanical area. |

|

FEEDING CONVEYORMakes the feeding of thin sheets and warped sheets seamless and effective. |

|

SIDE LAYThe side lay provides a sensor to ensure proper registration via an integrated photocell. |

|

GRIPPEREnhanced durability for the gripper bar and drive. |

|

CHASEChase turnover and center line ensures quick order change. An air floating device enhances the operational efficiency of the cutting plate. |

|

TOUCH SCREENClear and simple readings ensure quick fault finding and machine operation. Cutting pressure gauge ensures machine and cutting die durability by checking the cutting pressure and over-cutting pressure. |

|

STRIPPING SECTIONTriple action stripping with lower stripping pins. |

|

DELIVERY SECTIONAutomatic counter and tabbing inserter ensures reliability, productivity and batching. |