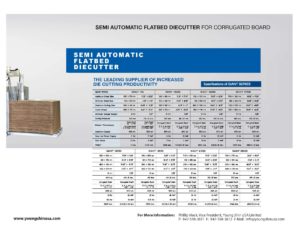

Young Shin GIANT – Models 105(S)

The Young Shin GIANT premier flatbed diecutter series incorporates both high-quality production and the integration of a fully-configured system for maximum productivity. The GIANT’s precise center line technology provides easy and rapid set up of the die board using the unit’s center block. Thin sheets feed smoothly and effortlessly with the GIANT’s enhanced feeding and conveying systems. The innovative air floating device allows easy withdrawal of the cutting plate for optimum operator efficiency. Two cameras are incorporated into the unit. One is placed within the stripping area and one is positioned in the delivery area. A monitor is located in the feed area for operator viewing. A variety of sizes are available to suit the needs of a wide variety of production environments.

Giant Series

| Model | GIANT 105(S) |

| Maximum Sheet Size | 41.33” x 29.52” |

| Minimum Sheet Size | 5.90” x 11.81” |

| Maximum Cutting Size | 40.94” x 29.13” |

| Inside Chase | 42.91” x 30.51” |

| Minimum Gripper Margin | 0.31” |

| Cutting Pressure | 275 US tons |

| Sheet Thickness | Carton Board : 0.01” ~ 0.05” Corrugated Board: E,B Flute) 0.39” |

| Maximum Speed | 3300 sph |

| Main Motor | 11 AMP |

| Weight | 12 tons |

|

FEED SECTIONSheets are fed manually by hand. Equipped with side guide for accurate insertion and registration. |

|

FEED SECTION CAMERAA camera is placed in the delivery area with a LED monitor displaying the feed area. |

|

MAIN OPERATION PANELA swingable main operation panel is provided that is simple to read, allows easy operator control, instant tracing and visual readings of the machine’s conditions. |

|

DIE CUTTING SECTIONThe centerline system supports quick die change and short set-up time. A knuckle system provides maximum cutting pressures. |

|

DELIVERY SECTIONProvides automatic high pile delivery with adjustable counter. Delivery section is equipped with side and back joggers for accurate stacking. |