Young Shin REVOTEC Automatic Flatbed Diecutter 1040S

The Young Shin Revotec 1040S is a premier automatic flatbed diecutter that offers significant productivity features while yielding numerous returns on its investment. The device’s clear and simple readings ensure quick fault finding and machine operations to support its 7,500 sph production speed. The Revotec 1040S’s cutting pressure gauge confirms that the diecutter and cutting die durability remain high by checking the cutting and over-cutting pressure readings. The side lay with sensor ensures excellent registration by more accurately approximating the distance between the side and front lay positions.

REVOTEC 1040S Series

| Maximum Sheet Size | 40.94” x 29.13” |

| Minimum Sheet Size | 17.32” x 13.38” |

| Maximum Cutting Size | 40.94” x 28.74” |

| Inside Chase | 43.30” x 30.07” |

| Minimum Gripper Margin | 0.31” |

| Maximum Speed | 7500 sph |

| Maximum Cutting Pressure | 330 US Tons |

| Sheet Thickness | Carton Board: 0.004” ~ 0.060”

Corrugated Board: E,B Flute (Max. 0.157”) |

| Weight | 17 US Tons |

|

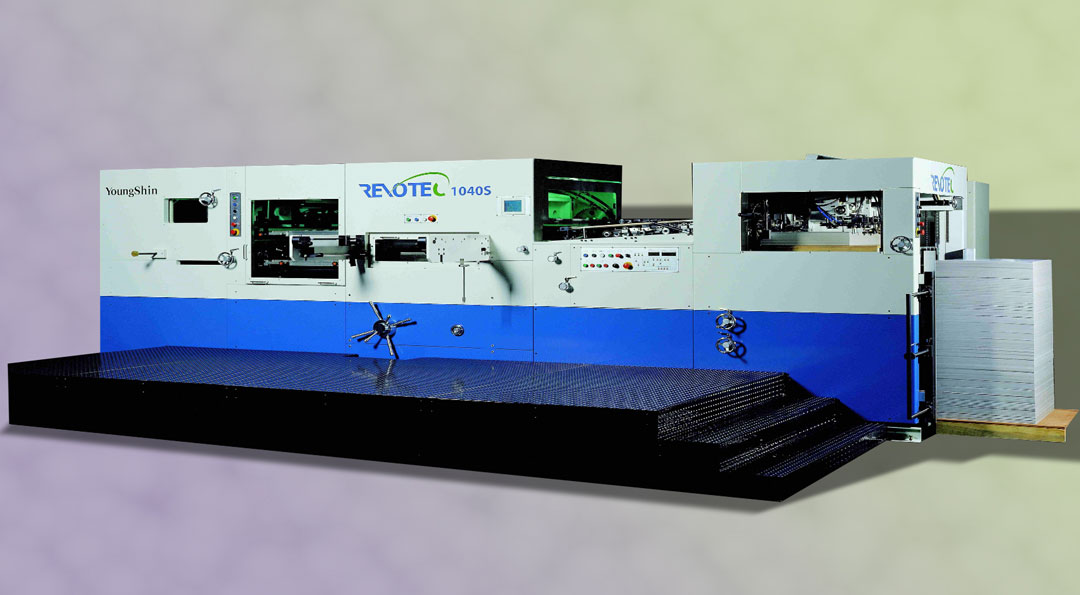

FEEDERWith suction device augmenting the mechanical driving, the inbound sheets are smoothly fed. |

|

FEEDING CONVEYORMakes the feeding of thin sheets and warped sheets both possible and efficient. |

|

SIDE LAYSide lay with sensor ensures precise registration by more accurately approximating the distance between the side and front lay. |

|

GRIPPEREnhanced durability of the gripper bar and drive promotes greater accuracy. |

|

CHASEChase turnover and center line ensure quick order change. |

|

TOUCH SCREENClear and simple readings provide quick fault finding and precise machine operation. The cutting pressure gauge confirms the diecutter and cutting die durability is accurate by checking both the cutting and over-cutting pressures. |

|

STRIPPING SECTIONWaste stripping utilizing both upper and lower pins. |

|

DELIVERY SECTIONAutomatic counter and tabbing inserter supports greater reliability, productivity and batching. |