Young Shin GIANT – Models 190, 210 and 250

Giant Series

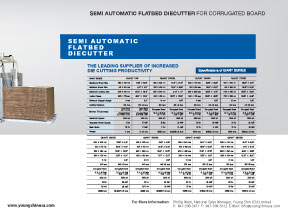

| Specification | GIANT 190(S) | GIANT 210(S) | GIANT 250(S) |

| Maximum Sheet Size | 1900 x 1300 mm | 2100 x 1500 mm | 2500 x 1700 mm |

| Minimum Sheet Size | 900 X 700 mm | 1100 x 850 mm | 2500 x 800 mm |

| Maximum Cutting Size | 1900 X 1324 mm | 2160 x 1531 mm | 2100 x 1690 mm |

| Minimum Gripper Margin | 10 mm | 10 mm | 15 mm |

| Cutting Pressure | 400 US tons | 500 tons | 500 tons |

| Sheet Thickness | Corrugated Paper (E, B, A, AB Flute) : 1.5 ~11 mm | Corrugated Paper (E, B, A, AB Flute) : 1.5 ~11 mm | Corrugated Paper (E, B, A, AB Flute) : 1.5 ~11 mm |

| Maximum Speed | 3000 sph | 3000 sph | 2000 sph |

| Required Power | 25 Kw | 30 Kw | 30 Kw |

| Total Weight | 24 tons | 34 tons | 47 tons |

EZ-FEEDER

| Specification | Based Upon GIANT 210 |

| Maximum Sheet Size | 82.67” x 60.50” |

| Minimum Sheet Size | 43.30” x 33.46” |

| Sheet Thickness | 0.05” ~ 0.43” |

| Maximum Speed | Depends on Machine Speed |

| Electrical Power | 480v, 60Hz, 3-Phase |

| Weight | .38 US tons |

| Length | 30.5” |

| Width | 51.8” |

| Height | 49.7” |

|

DIE CUTTING SECTIONChase turnover for easy order change. Knuckle system for maximum cutting pressure. Center line system for quick order change. |

|

STRIPPING SECTIONCenter line system maximizes quick set ups. Quick-lock device for male stripping frame. Triple action stripping (male, female and bottom). |

|

CHASE TURNER (OPTIONAL)Dramatically increases overall productivity and throughput. Allows the next job to be set up while the current job is running. |

|

GRIPPER EDGE REMOVAL DEVICE (OPTIONAL)Full stripping achieved with gripper edge removal device. Discharging gripper edge by auto conveyor. |

|

BATCH DELIVERY SYSTEM (OPTIONAL)Automatic counter ensures batch delivery. Non-stop delivery available via roller conveyor system. Side and back guides deliver perfect stacking. |

EZ-Feeder Specifications |

|

|

SUCTION FEEDStrong vacuum suckers and air separators ensure precise feeding. |

|

WARPED SHEET GUIDE AND FRONT LAY DEVICEWarped sheet device presses down sheet edge for even feeding into front lay assembly. |

|

SHEET SEPARATING BLOWERSAdjustable air pressure and position separates sheets. |

|

SHEET JOGGERSAir cylinder jogging units keep sheets arrayed at rear and sides for enhanced feeding. |

|

FEEDER VIEWPowered by chain transferring device and constant timing by clutch. |

|

MAN-MACHINE INTERFACEDisplays status of machine at all times for quick diagnosis. |

|

EZ FEEDER CONTROL PANELControls all electrical components related to the optional EZ Feeder, if installed. |

|

EZ FEEDER MAIN OPERATION BOXControls the function of the EZ Feeder’s vacuum pump and feeder head movements and engages the feed drive. |